Air Cooled Water Chiller and Water Cooled Chiller

Air Cooled Water Chiller and Water Cooled Chiller

Industrial chillers are robust refrigeration systems engineered to continuously remove heat from process water or fluids.

-

Air Cooled Water Chillers: These self-contained units use ambient air, drawn across a condenser coil by fans, to dissipate process heat. They are highly flexible and require no external water source or cooling tower, making installation simpler.

-

Water Cooled Water Chillers: These units use water from a connected external cooling tower to reject heat. They typically offer higher energy efficiency (better COP) and are ideal for large-capacity installations or where ambient temperatures are extremely high.

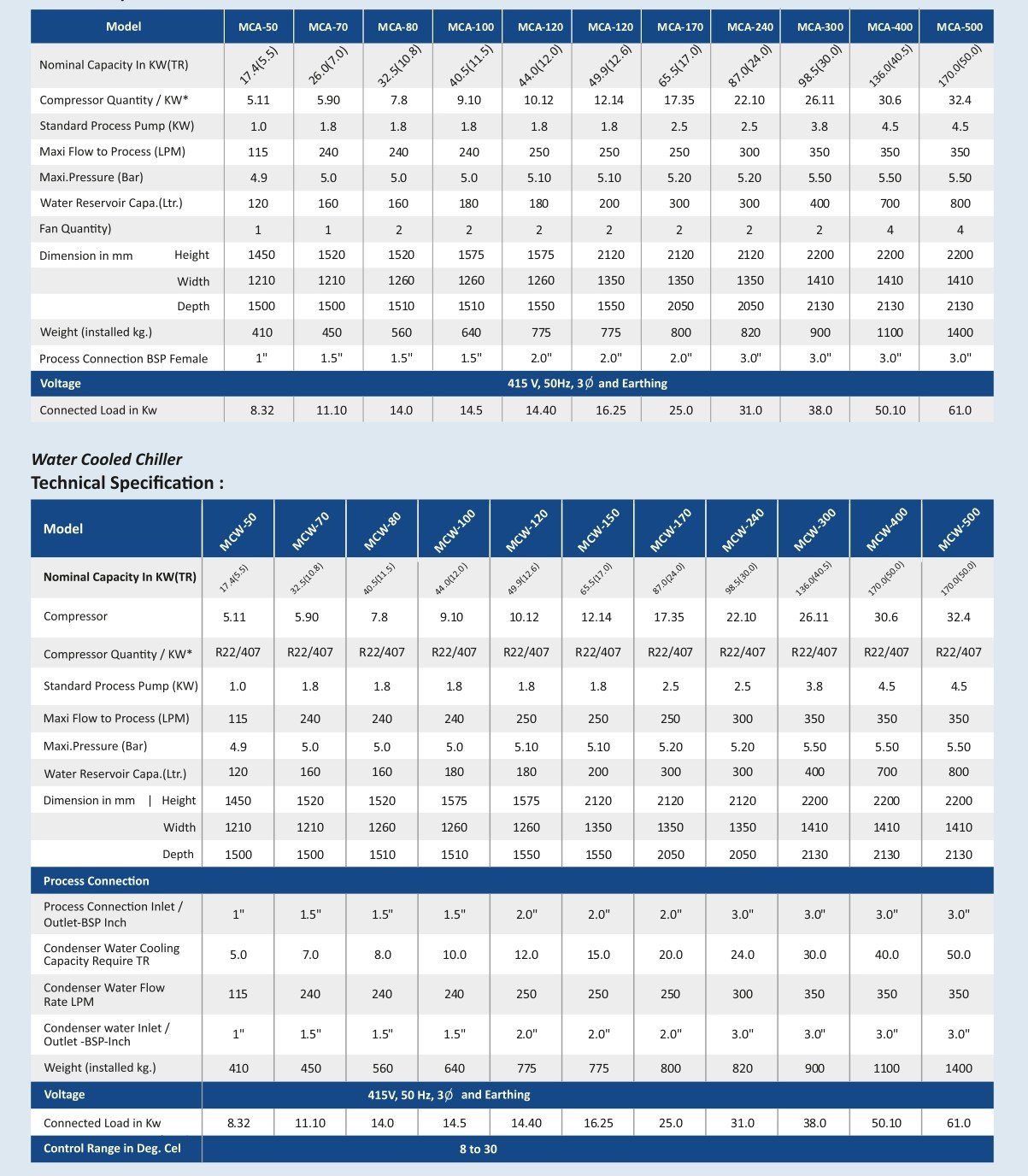

All our chillers are built with durable compressors, heat exchangers, and precise control systems, designed for 24/7 industrial demands (as shown in the technical specifications you provided, ranging from 17.4 to 170 nominal capacity in TR).

Advantages

Process Stability: Ensures consistent water temperature control, which is critical for product quality, especially in plastics, chemicals, and printing.

High Efficiency: Designs are optimized for maximum energy saving, offering a competitive advantage in operational cost management.

Machine Longevity: Prevents overheating of crucial production machinery (e.g., molding machines, hydraulic presses), significantly reducing wear, tear, and maintenance downtime.

Customizable Capacity: Available in a wide range of capacities (TR) and control ranges, including the multi-ton capacities necessary for large industrial facilities.

Complementary to Core Systems: Clean, conditioned water from our chillers works seamlessly with our Filtration Products to protect internal components from fouling and corrosion.

Applications

Plastics Industry: Cooling molds (supported by our MTCs) in injection molding, blow molding, and extrusion processes.

Chemical & Pharmaceutical: Cooling reactors, condensers, and maintaining stable temperatures for exothermic processes.

Printing: Cooling rollers and blanket wash systems in high-speed offset and digital printing presses.

Metal Finishing: Regulating temperatures in plating, anodizing, and heat treatment baths.

Controlled Environments: Providing stable cooling to Air Handling Units (AHUs) used in conjunction with our Clean Room Products.

Get In Touch

Interested in robust industrial solutions? If you have questions about our specialized equipment—including Filtration Products, Clean Room Products, Air/Water Cooled Chillers, Vertical Batch Color Mixers, Mould Temperature Controllers, Comprehensive Pump systems, And Ultrasonic Welding Machines—or if you require customized fluid dynamics, thermal control, or specialized process machinery projects, don’t hesitate to reach out.

We are dedicated to providing exceptional technical support and are committed to assisting you with all your industrial equipment and process optimization needs. Contact our manufacturing and engineering experts today.

High-Quality Material

Durability

Tested

Reliable Performance

Long

lasting

Customer Satisfaction