Vertical Batch Color Mixter

Vertical Batch Color Mixter

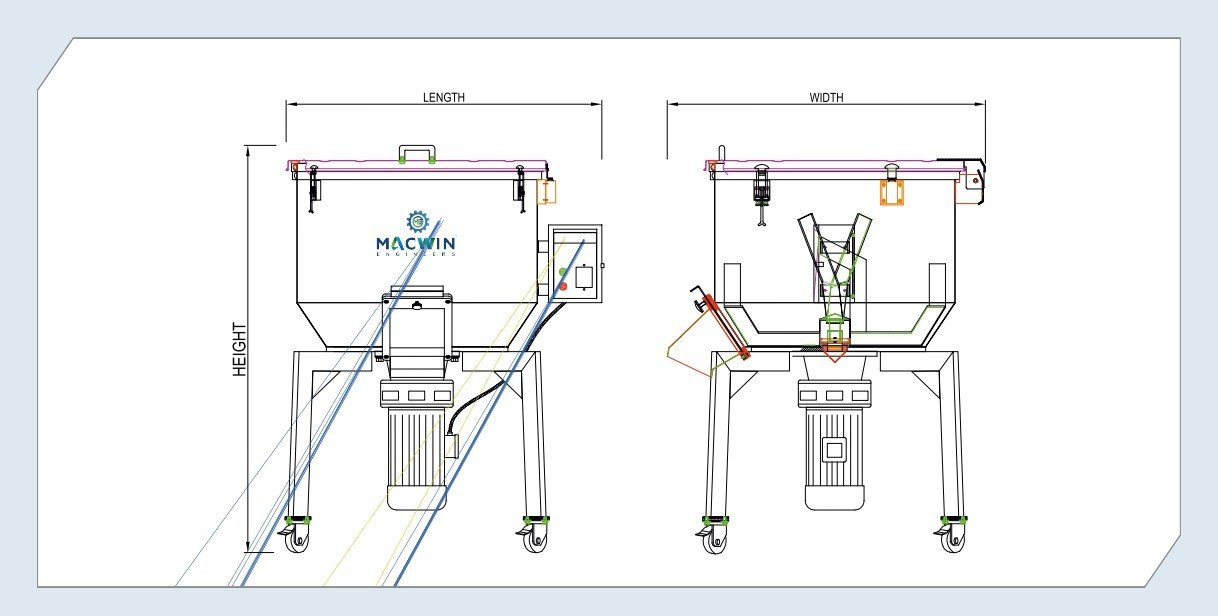

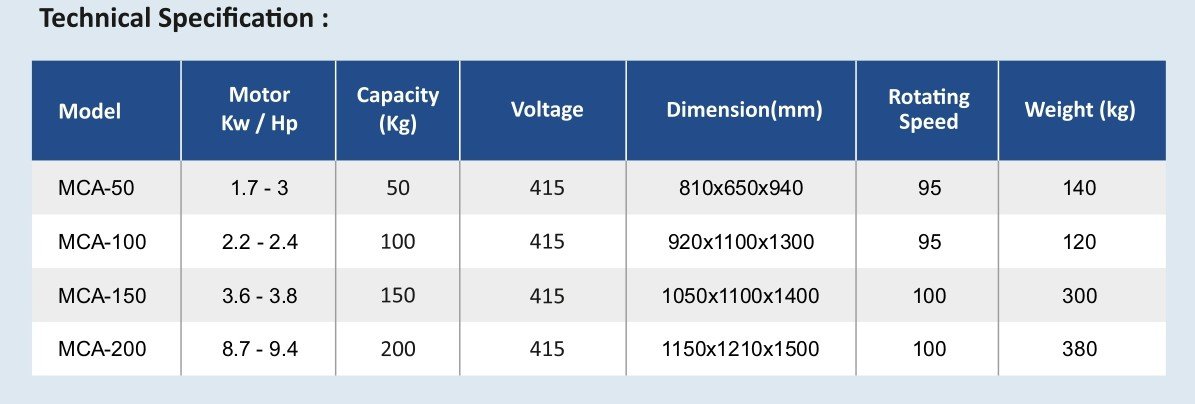

The Vertical Batch Color Mixer is a high-speed, high-efficiency machine specifically designed for the rapid and uniform blending of granular materials, plastic pellets, color pigments, and powders in precise batches (available in capacities ranging from 50 kg to 200 kg, as per technical specifications). The vertical design utilizes a central rotating agitator or ribbon screw that efficiently lifts and distributes the materials, ensuring thorough homogenization within short cycle times. The machine is typically constructed with stainless steel contact parts for durability and easy cleaning between batches.

Advantages

Uniform Mixing Quality: Guarantees precise and consistent color and additive distribution throughout the entire batch, eliminating streaks or variations in the final product.

Fast Cycle Time: Designed for quick loading, rapid mixing (high rotating speed of 95-100 RPM), and easy discharge, significantly boosting overall production throughput.

Easy Cleanout: The vertical geometry and accessible interior surfaces simplify cleaning procedures, which is vital when performing frequent color changeovers, minimizing contamination risks (much like maintaining a Clean Room).

Space Efficient: The vertical configuration requires minimal floor space compared to horizontal mixers of similar capacity.

Scalability: Available in multiple models (e.g., MCA-50 to MCA-200) to suit varying batch sizes and production needs.

Applications

Plastics Manufacturing: Blending plastic resins, virgin pellets, recycled materials, and masterbatches for injection moulding, extrusion, and compounding.

Color Concentrate Production: Preparing precise color mixtures before further processing.

Chemical & Powder Processing: Homogenizing dry chemicals, additives, and pharmaceutical powders where batch consistency is non-negotiable.

Process Line Integration: Preparing materials directly before they enter systems controlled by our Mould Temperature Controllers or processing equipment.

Get In Touch

Interested in robust industrial solutions? If you have questions about our specialized equipment—including Filtration Products, Clean Room Products, Air/Water Cooled Chillers, Vertical Batch Color Mixers, Mould Temperature Controllers, Comprehensive Pump systems, And Ultrasonic Welding Machines—or if you require customized fluid dynamics, thermal control, or specialized process machinery projects, don’t hesitate to reach out.

We are dedicated to providing exceptional technical support and are committed to assisting you with all your industrial equipment and process optimization needs. Contact our manufacturing and engineering experts today.

High-Quality Material

Durability

Tested

Reliable Performance

Long

lasting

Customer Satisfaction