Clean Room Products

Clean Room Products

A) Primary Garments

a) Antistatic primary Garments

b) Polyester Primary Garments

c) Disposable Normal Garments

d) Polyester Lab Coats

e) Antistatic Lab Coats

f) Cotton Lab Coats

B) Secondary Reusable Antistatic Garments

a) Coverall

b) Hood

c) Booties

d) Customised Reusable Antistatic Garments

C) Autoclavable Goggles

D) Autoclavable Shoes

E) Washable Shoes

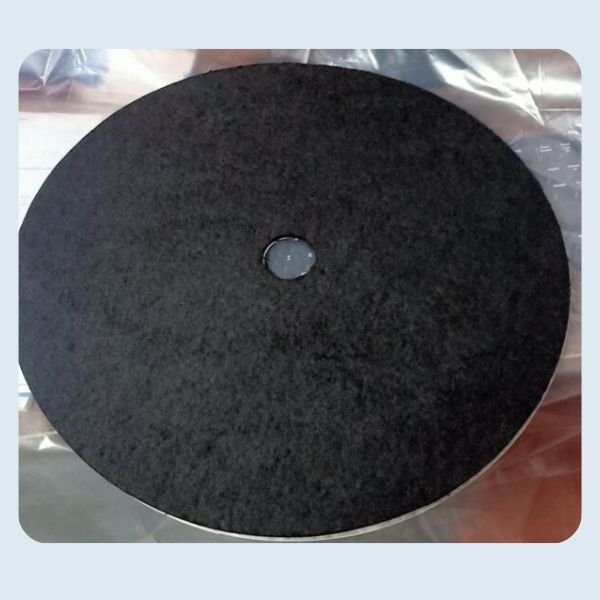

F) Sticky Mats

G) Sticky Roller

H) Autoclavable Wipes

I ) Flat Mops & Mops Cover

J) Autoclavable Pen & Marker

K) Cleanroom Paper

L) 1,2 & 3 Bucket trolley Cleaning System

M) Autoclavable Tape

N) Vnyle tape

Clean Room Products encompass specialized infrastructure and equipment designed to regulate airborne particulates, temperature, and humidity, ensuring compliance with strict international cleanliness standards . Our solutions manage everything from air filtration and pressure differentials to personnel and material transfer, offering complete control over the working environment. Key units include Laminar Flow Benches, Pass Boxes, and modular wall and ceiling systems.

Advantages

Contamination Control: Effectively minimizes the introduction and presence of airborne particles, microorganisms, and contaminants, protecting sensitive products and processes.

Regulatory Compliance: Helps clients in the Pharmaceutical, Microelectronics, and Medical sectors meet stringent national and international quality and safety regulations.

Operational Stability: Ensures consistent air quality, temperature, and pressure, which is vital for repeatable experimental results and manufacturing yields.

Controlled Transfer: Equipment like Pass Boxes allows for safe material movement between areas of different cleanliness levels without compromising the room’s integrity.

Applications

Pharmaceutical Manufacturing: Sterile filling lines, compounding, and primary packaging areas requiring GMP compliance.

Micro-electronics & Semiconductor Fabrication: Manufacturing of chips, PCBs, and sensitive electronic components that demand ultra-low particle counts.

Medical Device Assembly: Precision assembly and packaging of implants, surgical tools, and diagnostic kits.

Biotechnology & R&D: Controlled environments for cell culture, chemical analysis, and product testing.

Food Processing: High-risk areas requiring strict hygiene control to prevent biological contamination.

Our Products

Since 2014, SK Engineering Works has operated with an experienced team of engineers specializing in sales, design, quality check, and purchase, enabling us to offer a wide variety of precisely engineered solutions for Filtration Products and Clean Room Products. Our expertise ensures we meet every application need, from high-volume flow to absolute micron rating precision.

Get In Touch

Interested in robust industrial solutions? If you have questions about our specialized equipment—including Filtration Products, Clean Room Products, Air/Water Cooled Chillers, Vertical Batch Color Mixers, Mould Temperature Controllers, Comprehensive Pump systems, And Ultrasonic Welding Machines—or if you require customized fluid dynamics, thermal control, or specialized process machinery projects, don’t hesitate to reach out.

We are dedicated to providing exceptional technical support and are committed to assisting you with all your industrial equipment and process optimization needs. Contact our manufacturing and engineering experts today.

High-Quality Material

Durability

Tested

Reliable Performance

Long

lasting

Customer Satisfaction