Mould Temperature Controller

Mould Temperature Controller

The MTC is designed to circulate heated or cooled fluid (water or thermal oil) through the channels of a mold or die to maintain its temperature at an exact set point throughout the production cycle. This precise thermal management prevents defects and optimizes cycle times.

-

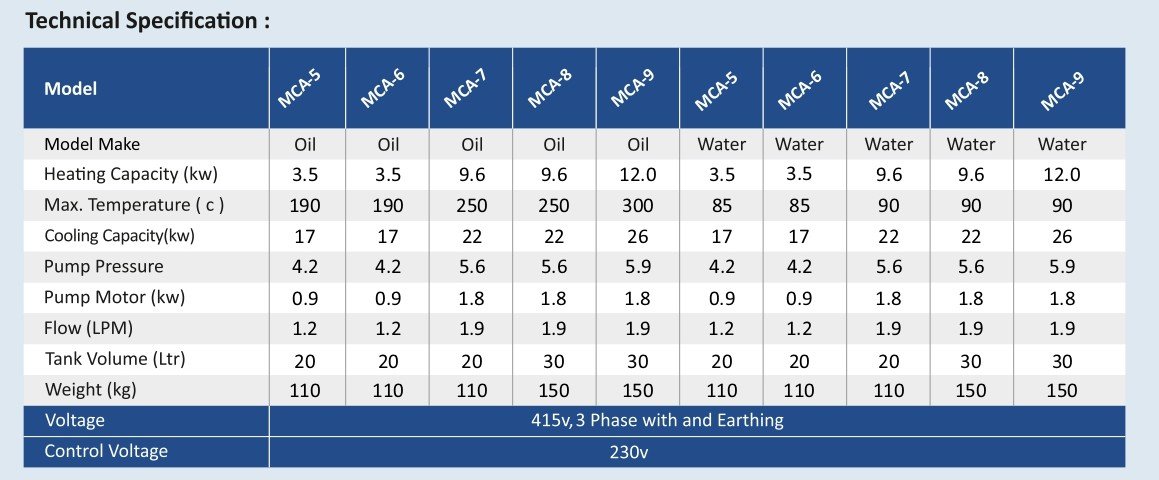

Water-Based MTCs: Suitable for temperatures up to $90^{\circ}\text{C}$ (or higher with pressurized systems). They are cost-effective and easy to maintain.

-

Oil-Based MTCs: Utilizes thermal oil to achieve very high temperatures (up to $300^{\circ}\text{C}$ or more, as shown in the technical specifications), necessary for high-performance plastics and specialized processes.

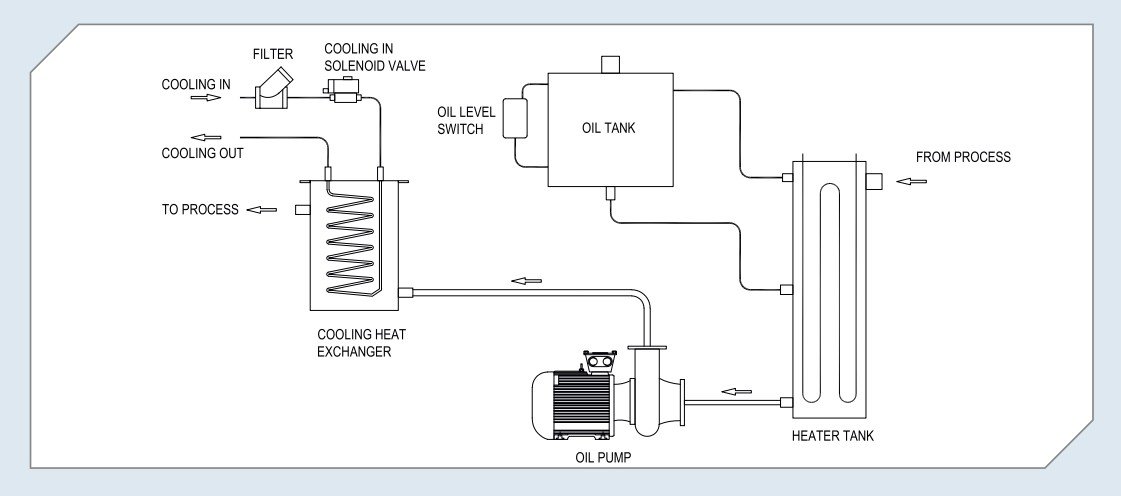

The MTC includes an integrated heating tank, a cooling heat exchanger, and a robust circulation pump to ensure efficient heat transfer, pressure, and flow (as indicated by the Pump Pressure and Flow in the technical table).

Advantages

Precision Quality Control: Maintains mold surface temperature within extremely tight tolerances ($\pm 0.5^{\circ}\text{C}$), eliminating defects such as warpage, shrinkage, and surface blemishes.

Cycle Time Optimization: Consistent temperature allows for faster cooling and solidification, significantly reducing overall production cycle times and boosting output.

Reduced Stress: Ensures uniform cooling, which minimizes internal stress in the molded parts, improving their mechanical strength and durability.

Versatility: Available in both oil and water mediums, capable of handling a wide range of temperatures and process requirements.

Applications

Plastic Injection & Blow Moulding: Essential for regulating tool temperature to achieve perfect surface finish and dimensional stability.

Rubber Curing & Compression Moulding: Providing necessary heat profiles for vulcanization and curing processes.

Extrusion Processes: Controlling the temperature of extrusion dies and calibration equipment.

Die Casting: Pre-heating and maintaining die temperatures in metal casting operations.

Supporting Purity: Ensures thermal stability, which is often a prerequisite for final packaging and inspection carried out in areas utilizing our Clean Room Products.

Get In Touch

Interested in robust industrial solutions? If you have questions about our specialized equipment—including Filtration Products, Clean Room Products, Air/Water Cooled Chillers, Vertical Batch Color Mixers, Mould Temperature Controllers, Comprehensive Pump systems, And Ultrasonic Welding Machines—or if you require customized fluid dynamics, thermal control, or specialized process machinery projects, don’t hesitate to reach out.

We are dedicated to providing exceptional technical support and are committed to assisting you with all your industrial equipment and process optimization needs. Contact our manufacturing and engineering experts today.

High-Quality Material

Durability

Tested

Reliable Performance

Long

lasting

Customer Satisfaction